Below are answers to frequently asked questions from engineers about our products, installation and maintenance. If your question isn’t answered here, please submit it using our contact form.

Yes. ACES offers two models to accommodate all buildings: pneumatic to connect to older thermostats and electronic to connect to both electronic and digital control systems.

At the heart of the system is the IAV Valve and Actuator Unit. It is designed to work with your existing units. Depending on the age and condition of your units, you may want to update with instruments that support the IAV valve: the IAV Controller™, the IAV Thermostat™, and the IAV Diagnostic Tool™.

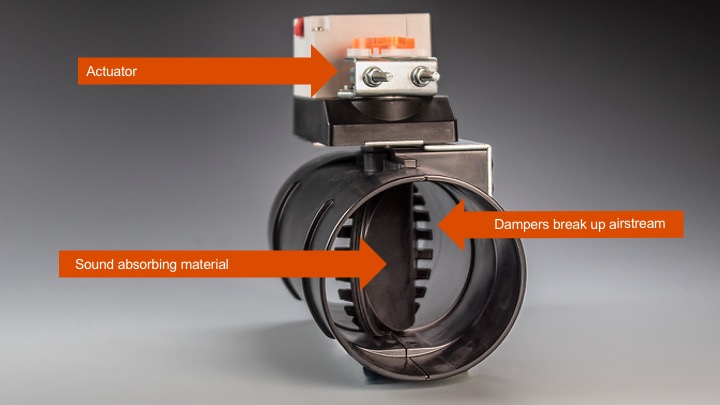

The IAV is revolutionary in design and performance. The valve is small with a 4” diameter that takes up only 4.5 inches of duct run when installed inside the existing unit inlet. The actuator, fed information from the thermostat and controller, opens or closes the airstream. A responsive damper inside the valve with multiple edge points breaks up the full airstream into mini airstreams, regulating airflow over the induction unit coil based on space requirements (VAV mode). Less air volume and a sound-absorbing core material substantially reduce noise from the induction unit.

The IAV is revolutionary in design and performance. The valve is small with a 4” diameter that takes up only 4.5 inches of duct run when installed inside the existing unit inlet. The actuator, fed information from the thermostat and controller, opens or closes the airstream. A responsive damper inside the valve with multiple edge points breaks up the full airstream into mini airstreams, regulating airflow over the induction unit coil based on space requirements (VAV mode). Less air volume and a sound-absorbing core material substantially reduce noise from the induction unit.

Installation takes as little as 10 minutes per unit.

The IAV Controller uses dedicated logic and requires no software or commissioning. It comes factory mounted and tested.

The IAV Controller uses dedicated logic and requires no software or commissioning. It comes factory mounted and tested.

All wiring to inputs and outputs are local except power and are plug-in-ready. There are no terminations. Power is provided over network cables from the home base and run to a single location on a floor, where they plug into a 24-volt power supply. One large power supply feeds the entire floor.

The IAV Controller provides a limited number of discrete inputs and outputs that direct the analog computers to change from cooling to heating and open and close air valves for isolation. While the controller itself does not communicate nor monitor, monitoring points like zone temperature, controller outputs and setpoints are available for BAS inputs. There is an option for remote setpoints to override local setpoints.

All control logic is built into the controller with limited required points to keep software-licensing costs down. In fact, only two digital outputs are required per floor.

Typical costs for this system are less than $700 per unit and software-licensing costs can be negligible. Central BAS System induction units can cost up to $3,500 each, while Distributed (Smart) units can approach $3,000 each.

Our controller features all industry standard input and output signals that are compatible with any Building Automation System (BAS) old or new. Just terminate these signals into your BAS system and program the points and you are ready to go. In addition, we will supply a custom termination board that will plug into your BAS without the need for time consuming manual terminations.

Like the IAV Controller, the IAV Thermostat is designed to work with the IAV System. It houses a very responsive Platinum RTD sensor. This sensor reacts much faster to changes in room temperature and is more precise than a pneumatic bulb. Temperature can be maintained to +/- one-tenth of a degree.

A Platinum RTD can be mounted in a thermostat box enclosure with a digital readout on the wall or on the induction unit with a digital display and membrane switches to change setpoint.

A Platinum RTD can be mounted in a thermostat box enclosure with a digital readout on the wall or on the induction unit with a digital display and membrane switches to change setpoint.

The IAV Diagnostic Tool maintains optimal performance. It monitors energy saving functions and pinpoints where trouble is occurring. Maintenance is quick, usually exchanging one piece or part with another, keeping downtime and repair time to a minimum.

The IAV Diagnostic Tool maintains optimal performance. It monitors energy saving functions and pinpoints where trouble is occurring. Maintenance is quick, usually exchanging one piece or part with another, keeping downtime and repair time to a minimum.

The IAV is now used to control the capacity of the induction unit. The water valve is left fully open except at those times that the space overheats and we want to stop any convection from the unit at which time we close the water valve. You should not have to replace it.

Your pump’s HP is less than 20% of the fan HP. By reducing water flow, you would increase fan HP and the overall HP would actually be higher if you reduced the water flow by your pump.

Your freeze protection is actuated by dropping the pneumatic air pressure on the control system which forces the normally open water valves to open. This remains the same and so your freeze protection is not affected.

The supply fans need to have a variable speed drive to reduce supply airflow and pressure. They should be controlled from a pressure sensor that reads the discharge pressure on the fan and slows the fan down as the pressure increases in response to the IAVs throttling the airflow down.

The old temperature sensor was at the floor level in the return air to the Induction unit. This was good at keeping your feet satisfied but ideally ASHRAE says a room thermostat should be at 48 to 54 inches high. Ideally it should be installed out of direct sunlight about halfway down the room at 50 to 52 inches above the floor. You will be supplied with a premade cable to install it there. It can also be installed on a column or on the induction unit face itself.

We have tested a variety of methods and products to connect the IAVs to the ducts and to the Induction units. The answer to what is best depends on the fitting clearances for the particular application, the room to work inside the cabinets, the condition of the existing ductwork, the material of the existing ductwork and the preferences of the installers. If there is room, a glue gun with a special glue works very well. There are rubber and fabric couplings with captured hose clamps that are available through us and others, new hoses available from Grainger and many other suppliers along with new hose clamps, spiral pipe and fittings available through us and through others. Heat shrink tubing gives you a good seal. We will work with you to test and select the best installation answer for your application.

This is a choice specific to each building. Some of the questions that need to be addressed are:

In some cases, going back to the old pneumatic valves may be the best choice and in others an electronic valve may be the best choice. We can help you make that choice and can provide the valves if you so choose.

For the past 50 years or so you have not monitored any points. When a tenant complained, you responded.

Now there are valuable pieces of information available that can help you operate your system better and save energy. There are also some large rebates (33%) that encourage you to monitor points that help you operate better.

We recommend that you add enough points to get the rebate but don’t drive costs too high. For this reason, we designed the Analog Computer System to provide all the energy saving functionality with a limited number of points to be monitored and controlled. These points provide the information necessary to document the operation and develop and implement an optimization strategy. You can control the floors with two digital outputs per floor. If you want to collect data and optimize the operation, you have the inputs and outputs to choose from. Our buildings operations experts can help you develop your strategy.